Building a FFF 3D Printer

Fused Filament Fabrication or FFF is a type of 3D printing technology where parts are created through a layer-by-layer deposition of a molten thermoplastic. The extruder is responsible for heating up plastic filament and is fitted with a nozzle that controls the dimeter of the extruded fiber. It may help to think of the extruder as a fancy hot glue gun that is strapped to a series of rails that allow it to move in three dimensions, depositing material layer-by-layer.

Build it Yourself

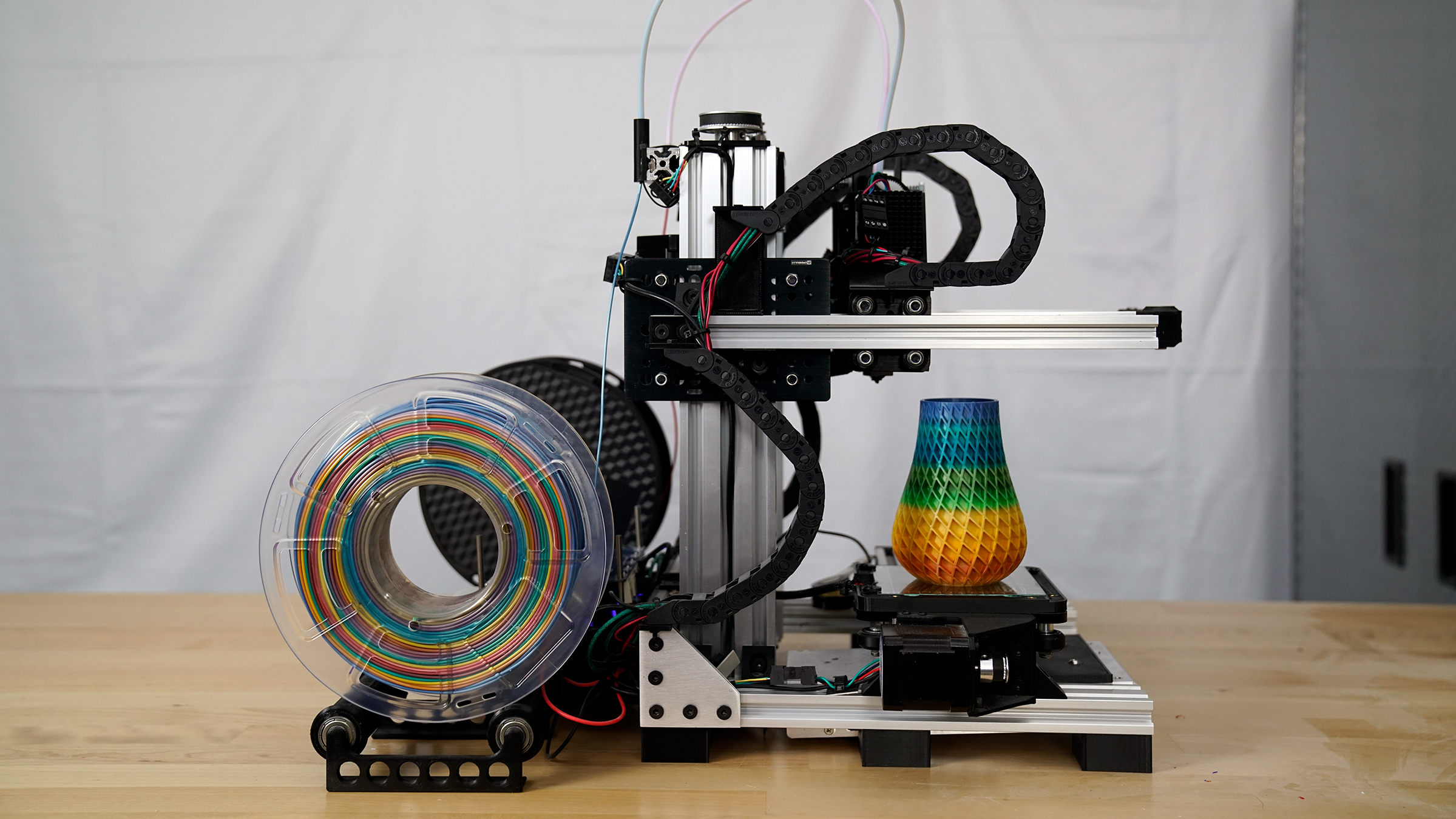

The natural progression of 3D printing as a hobbyist is to buy a 3D printer, print a couple trinkets, realize that a 3D printer can print parts for another 3D printer, and then build a second printer. This is a slippery slope where you could unintentionally end up with more than a couple printers. Nevertheless, taking on the challenge of building your own 3D printer is not only fun but it is also an academic exercise where you will learn about linear motion, electronics, and a little bit of programming.

Do Some Research

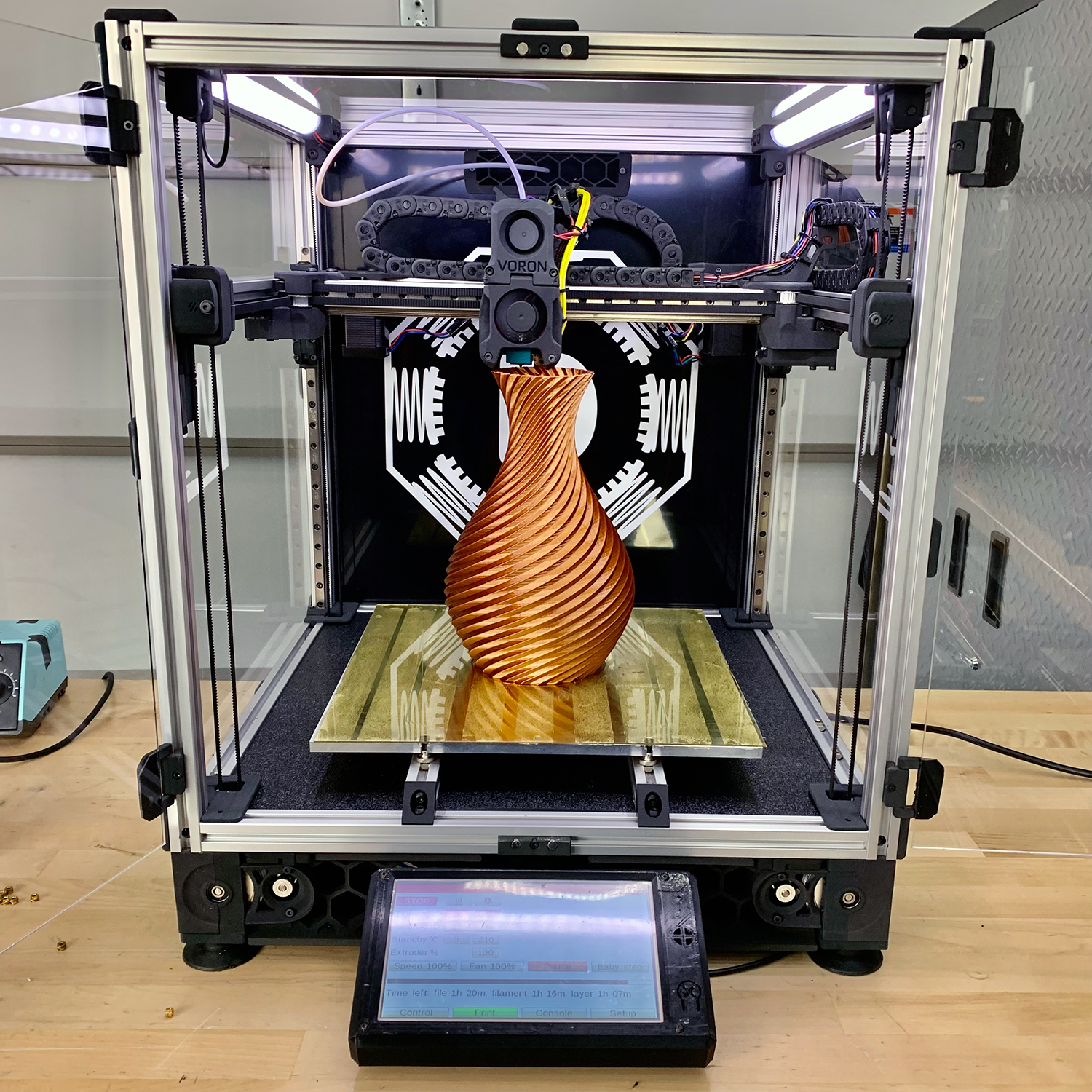

Whether you are purchasing a kit or sourcing your own parts understanding the function of each component will allow you to build, upgrade, and repair your 3D printer with ease. This written guide (once complete) will contain Dr. D-Flo’s most up-to-date information on the theories and parts that make up a 3D printer. If you are more of a visual leaner, then checkout Dr. D-Flo’s 3D printing playlist for videos on the fundamentals of 3D printer building and how to build Voron 2.4 – one of the most popular DIY 3D printers today.

Ask Questions and Share

After exploring the topics below post your remaining questions to the forum. This guide will be improved based on your questions and comments. After finishing your printer, please consider sharing your design and experiences.

Have you chosen a printer design?

If you are still undecided on what printer you want to build, then check out Dr. D-Flo’s roundup of the Best DIY 3D Printer Designs.

Essential 3D Printing Topics

Explore the topics below for an indepth overview of all the parts and theories that go into building a 3D Printer. If you are new to 3D printing, then it is recommended to go in order of the topics. Also, most of this information is useful for building any kind of CNC machine.

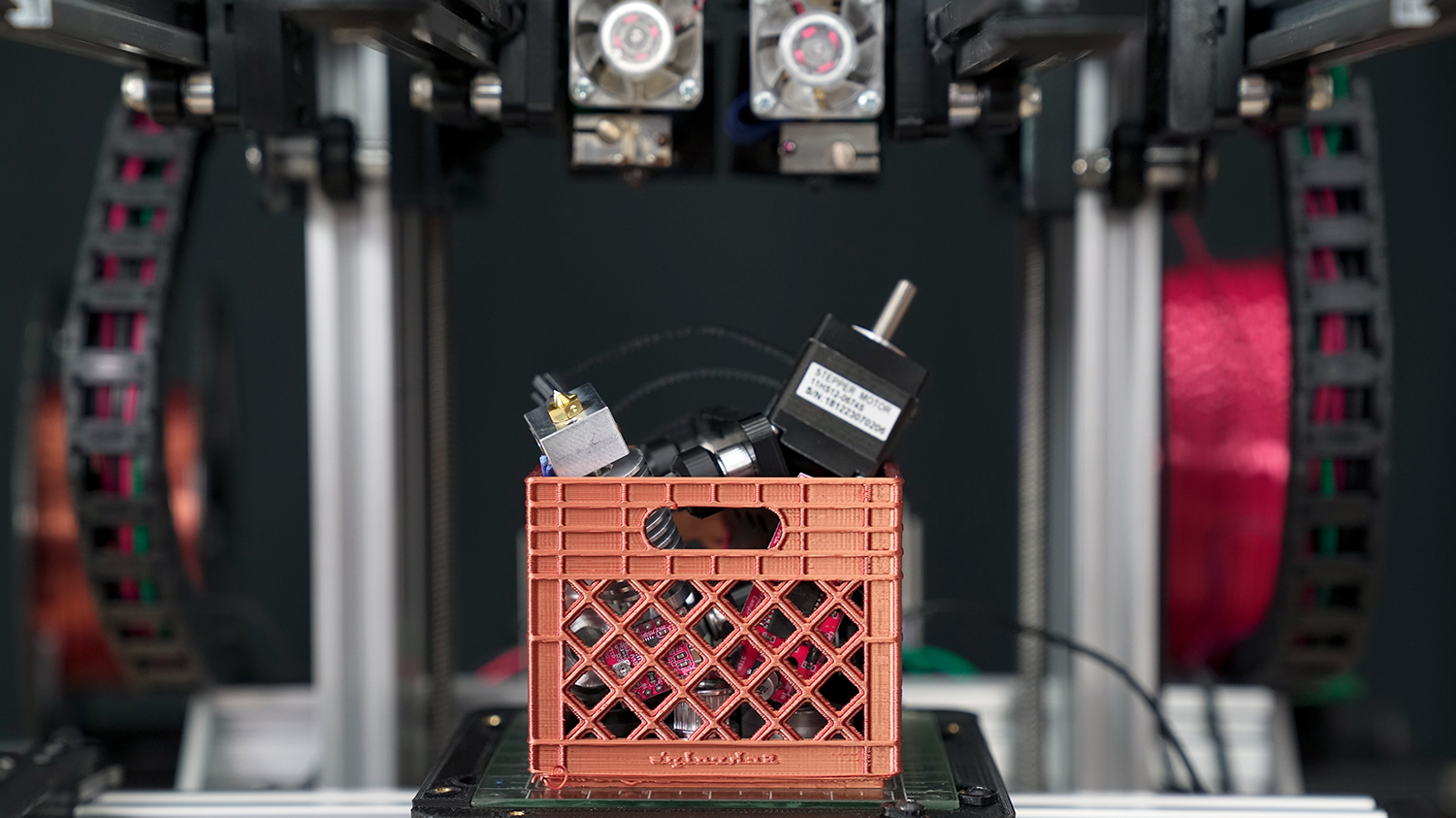

1. Tools and Supplies

Here are all the tools you need to build and properly calibrate a 3D Printer.

Learn More

2. Extruder

The way in which the extruder liquifies and deposits filament onto the build platform is the defining characteristic of FFF technology.

3. Linear Rails

Precise linear motion is required for 3D printing. Linear rails act as a guides for motion carriages and in some cases, play a dual role as the frame for the 3D printer.

Learn More

4. Linear Rods

Cylindrical guides are affordable alternatives to linear rails. Bearings slide along the rods to provide free motion in the direction of the rod.

5. Linear Carriages

Carriages ride on top of linear guides, translating their cargo in the direction of the guide. The best carriages provide smooth and low friction movement.

6. Transmission

Lead screws and pulleys convert the rotational movement of a motor shaft into linear motion. 3D printers require precise transmission systems to function properly.

Learn More

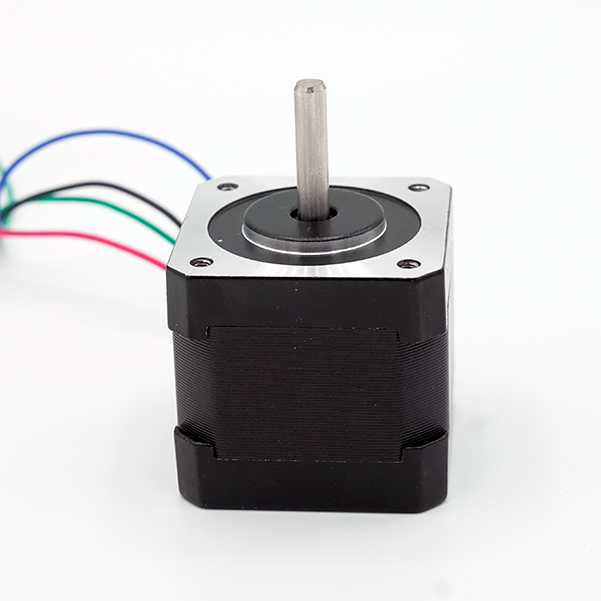

7. Stepper Motors

Stepper motors are brushless DC motors that can move accurately without positional feedback. They are a cheap alternative to servo motors.

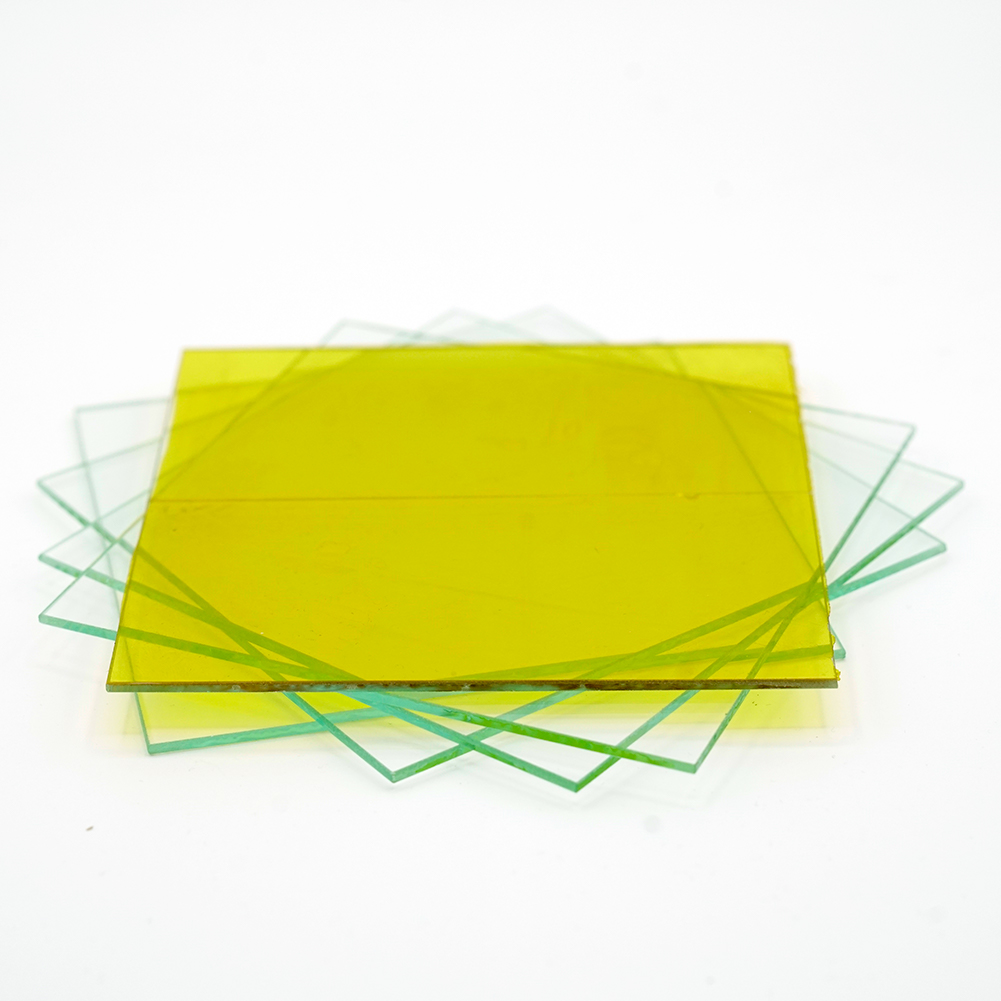

8. Print Bed

The print bed is the surface that the first layer of the print comes in contact with. A heating element and special adhesives can prevent the 3D print from warping and falling off.

Learn More

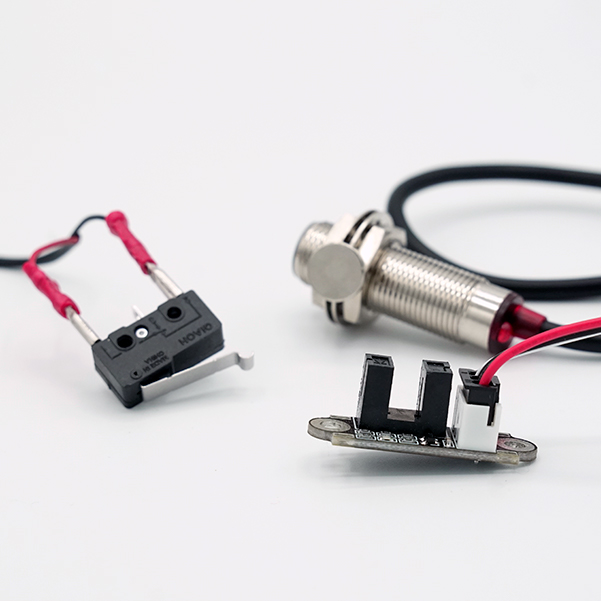

9. Limit Switches

Limit switches are sensors that allow the 3D printers to find the ends of the their linear guides. The most common type of limit switches are triggered by mechanical force.

Learn More

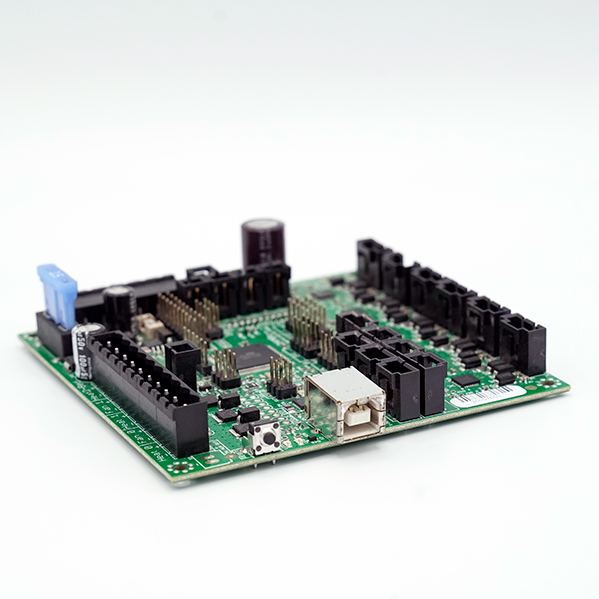

10. Motherboards

The motherboard houses the microcontroller which is the brains of the 3D printer. All of the electrical components are plugged into the terminal or ports present on the board.

Learn More

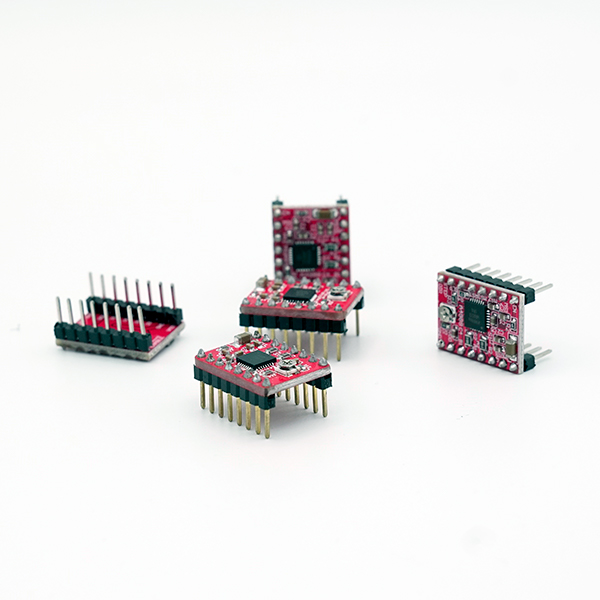

11. Stepper Drivers

Stepper drivers orchestrate the pulses of current that causes the stepper motor to step. The driving mode of the stepper driver will influence the step size of the motor.

Learn More.png)

12. Microstepping

Microstepping is the process of dividing a stepper motor’s intrinsic full step into many small steps to improve the resolution of the linear motion.

13. Power Supply

A regulated DC power supply is required to power most if not all of the 3D printer components. 12V and 24V are common voltages accepted by the printer’s motherboard.

Learn More

14. Wiring

Motors, extruders, and limit switches need to be wired to the motherboard. It is important that the wiring does not restrict the motion of the extruder or pose a fire hazard.

Learn More

15. Firmwares

Firmware runs on the printer's microcontroller and stores printer-specific parameters. These unique values allow the firmware to translate generic G code into real life objects.

Learn More

16. Slicers

Slicers are software programs that convert digital 3D objects (STLs) into G code, which describes positional coordinates and speeds to the microcontroller.

Learn More

17. Calibration

Properly calibrating a 3D printer can improve dimensional accuracy and surface finish of prints. Filament feed rates and extruder movement speeds need to be fine-tuned.

Learn More

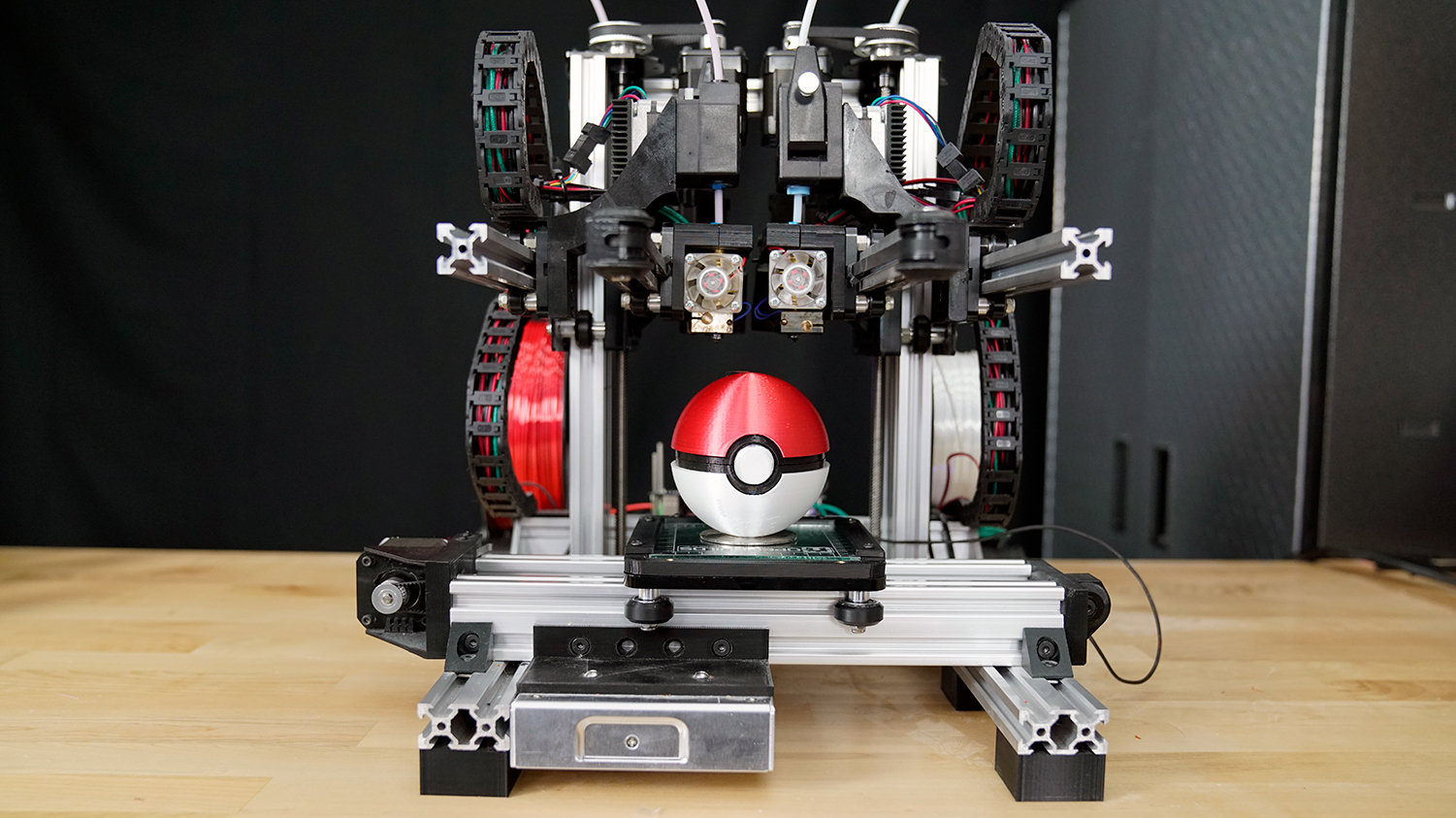

18. Dual Extrusion

A 3D printer will dual extruders can print multi-material or multi-color parts. However, additional calibrations are needed for seamless switching of the extruders mid-print.

Learn More

19. Filament

Filament is plastic feedstock of constant diameter that is fed into the extruder. There are numerous filaments available from reliable PLA to exotic composites.

Learn More