Overview

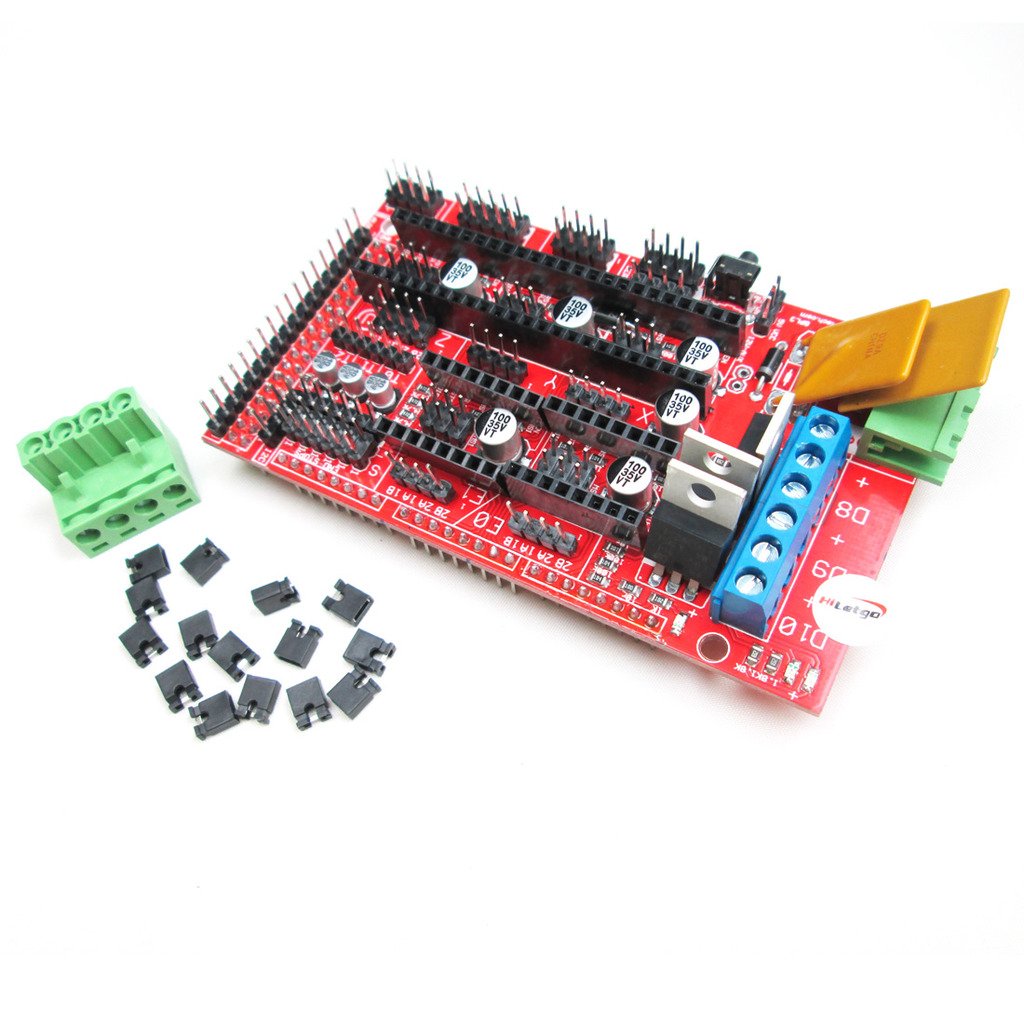

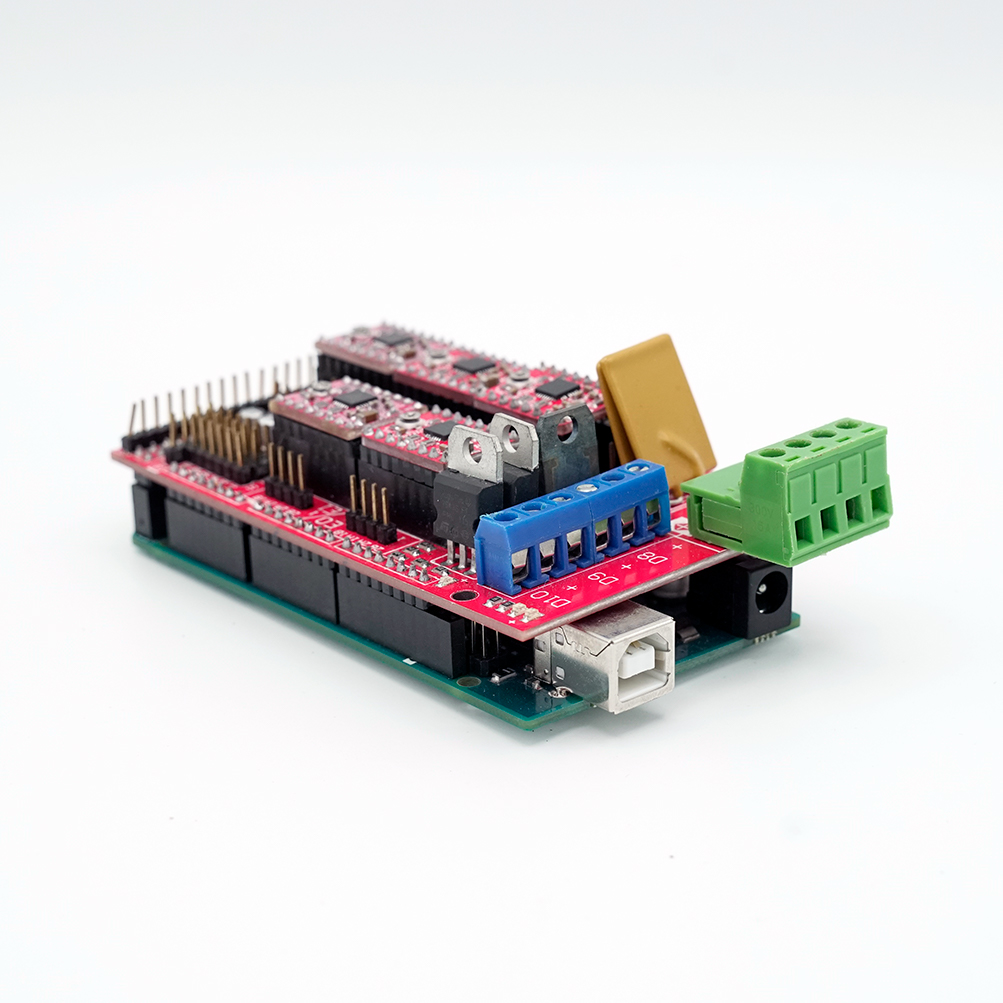

All the electrical components will be connected to the printer motherboard, which houses the microcontroller. It’s the microcontroller’s job to enact the code from the 3D printer software to ultimately produce a 3D printed object. This job includes not only barking orders, like telling the stepper drivers when and in what direction to move the motors, but also requires the microcontroller to listen and respond to various inputs like the extruder temperature or the state of the limit switches. It is the motherboard’s responsibility to provide the physical connectors for these outputs and inputs. The number of stepper motors, heaters, sensors and buttons that are supported is often a deciding factor when purchasing a motherboard. However, there are many other features, such as the presence or absence of a certain type of stepper driver, that will weigh into your decision to go with one motherboard over another. This section will outline the minimum capabilities of a few popular motherboards that exist on the market. I recommend reading both the stepper driver and motherboard firmware sections to figure out which motherboard is the best match for your 3D printer build.

Printer-Motherboard Compatibility

Number of Extruders

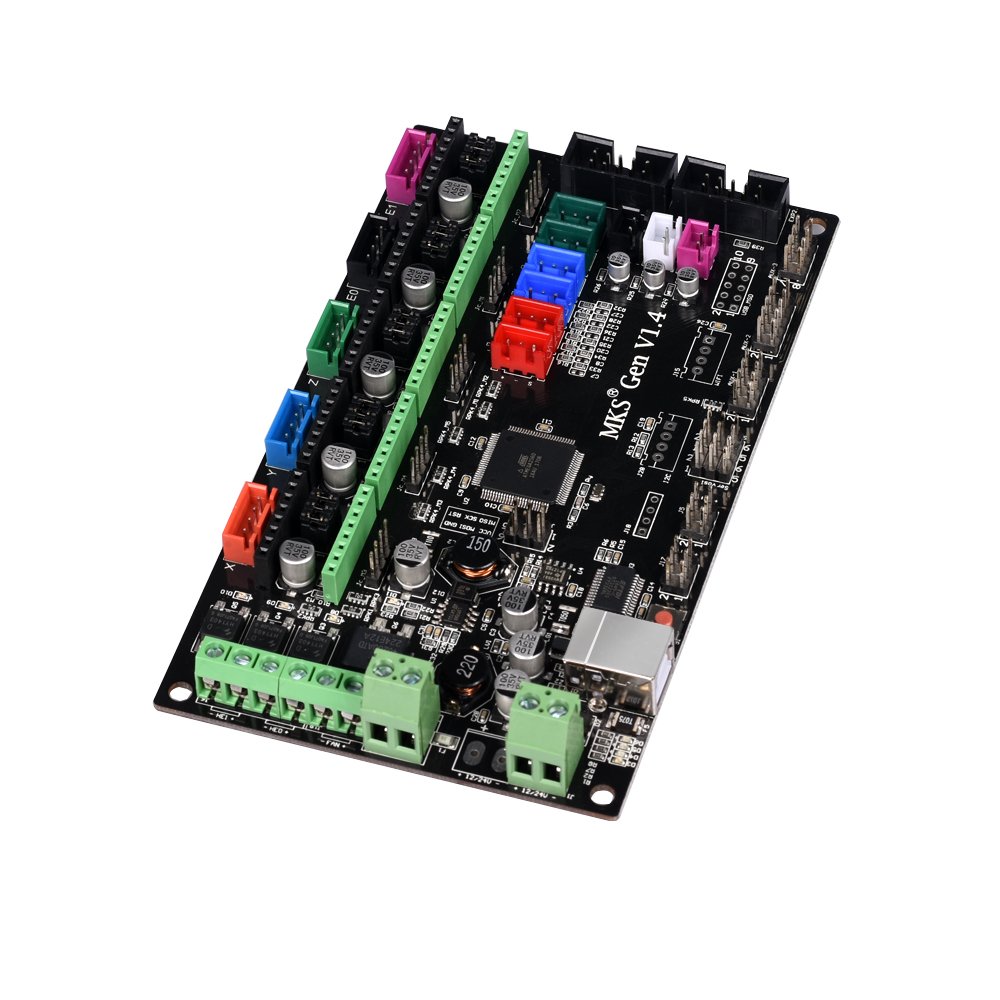

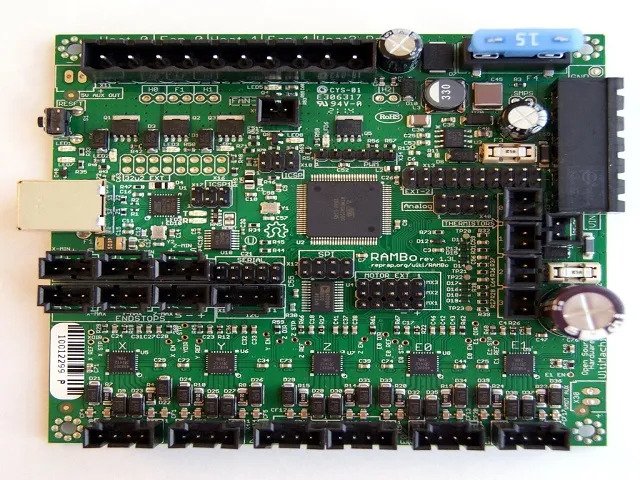

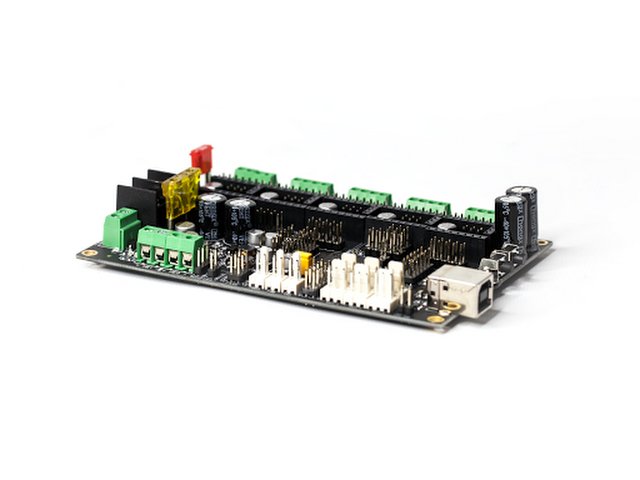

First and foremost, the motherboard should be chosen based on how many extruders your printer will have. The easiest way to achieve multi-material prints is to incorporate more extruders into the printer’s design. These additional extruders can all be fixed to the same carriage, which is known as a fixed extruder setup, or they can ride on their own independent rails, which is known as an independent extruder setup. Multi-material 3D printers will be discussed more in their own section, but it should be fairly obvious that more extruders will require additional ports on the motherboard. Nearly all motherboards support up to two extruders fixed on the same carriage, but if you want to build a more exotic 3D printer with more than two extruders or extruders on independent carriages then you have to select your motherboard carefully. The recommended motherboards for single or fixed dual extrusion listed in order of increasing price are MKS Gen 1.4, Azteeg X5 GT, and RAMBo 1.3. For more complex builds, the Duet Wifi can support up to 7 extruders and 10 stepper motors (2 more stepper motors can be added with external stepper drivers).

3D Printer Geometry

Most people will choose to build a cartesian 3D printer, where the linear guides resemble the x, y, and z axes of a cartesian graph. By default all printer motherboards support this “geometry,” but other geometries exist. The second most popular 3D printer geometry is known as delta. Delta printers are the tall and skinny printers with a circular build platform. Read more about delta printers here. Delta printers use almost the same number of electrical components (e.g. stepper motors, limit switches, etc.) as a cartesian printer, so in theory if a motherboard can control a cartesian printer then it should be able to control a delta printer. However, this is not always the case and is usually a limitation of the motherboard’s software, known as the firmware, and not the motherboard’s hardware. If you are building a 3D printer with a less common geometry, then make sure the motherboard you purchase has the firmware to support it. Firmware is discussed further in its own section.

Motherboard Features

Once you have determined which motherboards are compatible with your 3D printer design, then you can narrow your choices down by determining which quality-of-life features are worth the added cost. By quality-of-life I mean features that are not necessary for the functionality of the printer but will make the build and operation of the printer more enjoyable. I have compiled a small list of these quality-of-life additions below.

-

- 24V Input Voltage - 24V is the unofficial new standard for powering stepper motors, extruders, and heated bed over the old 12V standard. Purchasing a motherboard that supports 24V will allow for smaller gauge wire to be used when connecting all the components and for better stepper motor performance (see power supply section).

- 32 Bit Processor - Most motherboards have an 8-bit microcontroller that runs all the electrical components of the printer, but this processor can struggle to keep up with all the task required to make a 3D printer run properly. High end motherboards use 32-bit processors that can quickly calculating complex motion paths, resulting in quieter and better prints.

- Internet Connectivity - The presence of a wifi or ethernet module on the motherboard will allow for remote monitoring of your prints. Throw in a wireless camera and you can cancel failed prints while away, saving filament and possible injury to the printer.

- Spare IO Pins - Motherboards with accessible and unused IO pins opens up the ability to seriously customize your printing experience. These IO pins can trigger a camera to take a picture of the print after each layer or they could be used to turn on LEDs after the print is finished so you can inspect your part.

External Resources

There are a lot of different ways to successfully build a 3D printer, many of which are not covered on this website. If you want to learn more about printer motherboards, then click through some of the links below to external websites and forums.

Recommended Products

The table below contains parts specific to this section that Dr. D-Flo uses and recommends. Depending on your printer build these parts may or may not be compatible. It is best to use the products below as a launching point to explore similar products on the linked websites. Affiliate links may be present below (depending on the vendor).