Overview

When designing a linear motion system for a 3D printer, you have two choices for the guides that the components will ride on. The first choice is a rail. Similar to railroad tracks, a carriage rides on top of the rail which is typically supported from underneath. The carriage can only move in the direction that the rail is pointing. The second choice is a cylindrical guide known as a linear rod. Linear rods will be discussed in their own dedicated section, so we will focus on linear rails here.

Choosing a Linear Rail

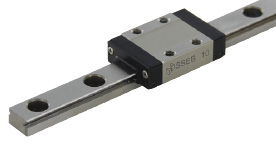

"Traditional" Linear Rail

A “traditional” linear rail is a thin and long rectangular piece of steel with two dovetails that run along either sides. Hardened or stainless steels are the materials of choice because even rails with small cross-sectional areas resist flexing. Further, steel is relatively easy to machine, so tight tolerances are possible. In linear motion, tight tolerances usually refers to how straight the rail is. It should go without saying that any bend or flex in the rail would affect print quality. The dovetails cut into the length of the rail are where the ball bearings of the carriage ride. Properly lubricated rails will perform smoothly for a long time. The two drawbacks of using “traditional” linear rail in a 3D printer build are the price and the need for a physical frame to attach the rails to. Quality rails and their matching ball bearing carriages from a reputable company like McMaster-Carr will usually cost an arm and a leg. For this reason, many DIYers tend to purchase import rails with questionable quality control. Once you have your hands on enough linear rail for each axis you will have to create a frame to attach the rail to. Typically, the frame is constructed out of aluminum extrusion. But why can’t the aluminum extrusion act as the rail?

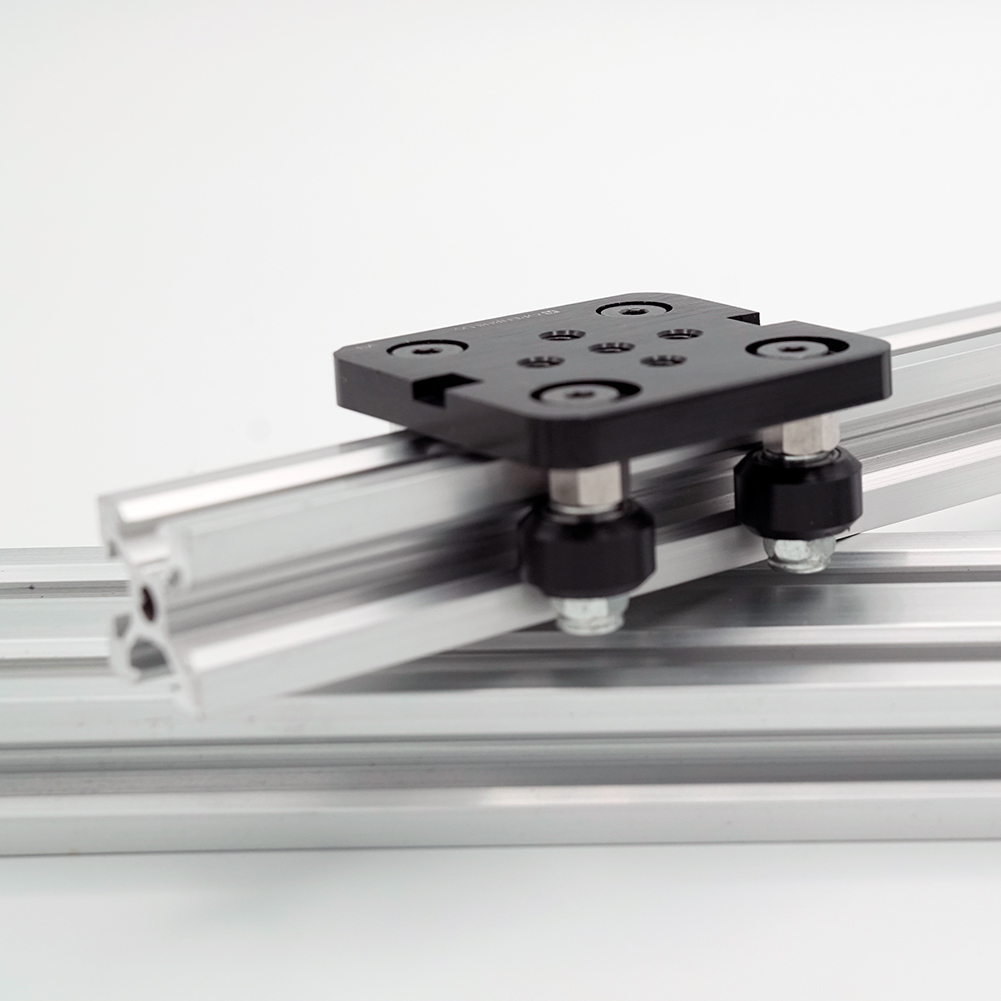

ALUMINUM EXTRUSION RAIL

The answer to that last question is that aluminum extrusion can in fact act as linear rail. There are a couple of different types of aluminum extrusions that are suitable for linear motion. Most of these extrusions have some sort of V-geometry that creates a track for wheels to move on. This V-geometry is also the namesake for this class of aluminum extrusion, which is known as V-rail. The ability for the V-rail to act as both the linear axes for the 3D printer as well as the frame may sound too good to be true, but trust me, I have had a lot of success with these linear rails. However, there are a couple drawback to be aware of. Aluminum is not as stiff as steel, so for large format printers the V-rails need to be supported throughout the run. The perfect case would be to have steel V-rails, but it is difficult to extrude steels through complex profiles and machining the steel into V-rail would be too expensive. The other drawback of aluminum extrusion is that the delrin wheels that ride on the rail will have a shorter lifespan than the ball bearings that ride on the “traditional” rails. Even with these shortcomings, V-rail is a great system for building a 3D printer around.

External Resources

There are a lot of different ways to successfully build a 3D printer, many of which are not covered on this website. If you want to learn more about Linear Rails, then click through some of the links below to external websites and forums.

Recommended Products

The table below contains parts specific to this section that Dr. D-Flo uses and recommends. Depending on your printer build these parts may or may not be compatible. It is best to use the products below as a launching point to explore similar products on the linked websites. Affiliate links may be present below (depending on the vendor).