Must have more printers!

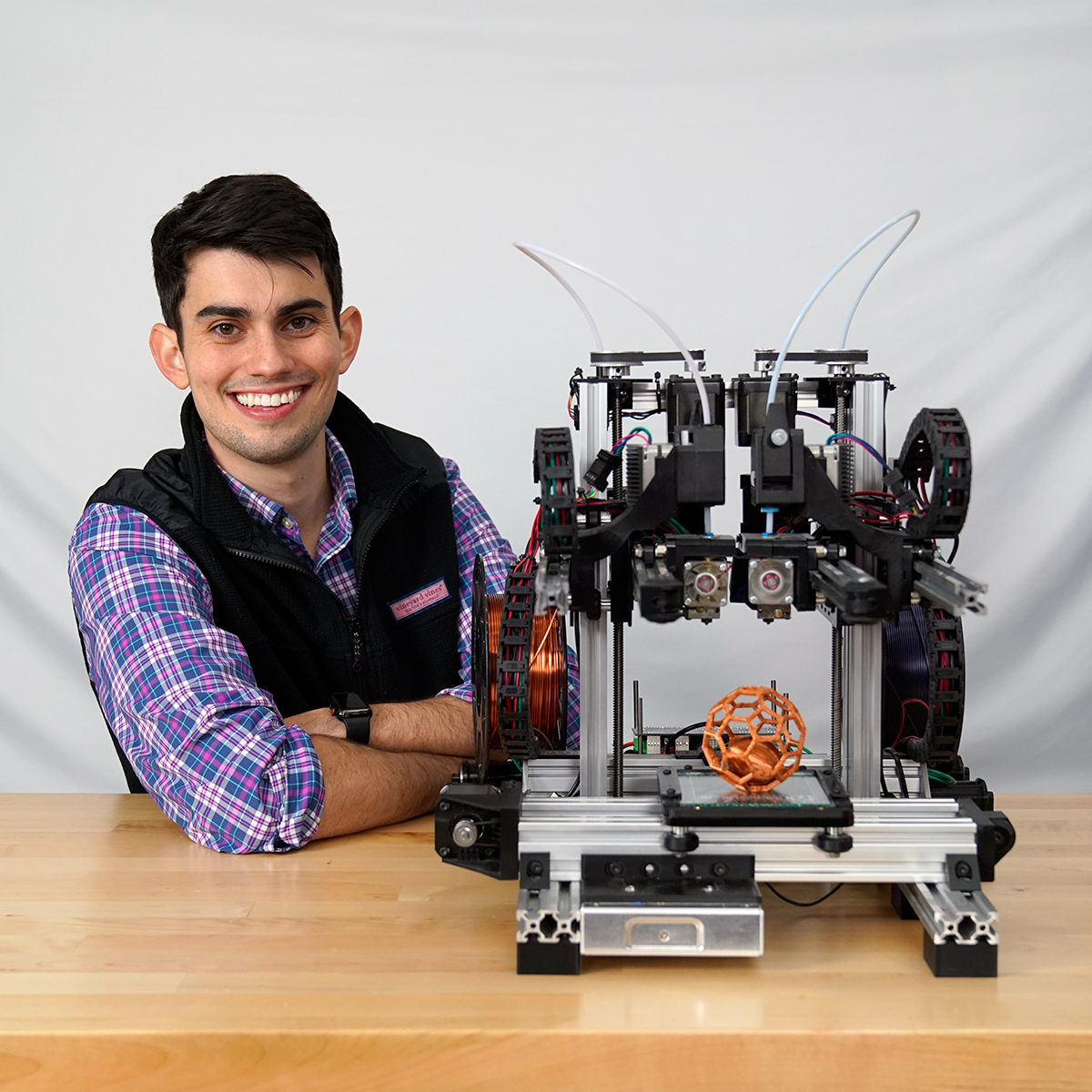

3D printing is an addictive hobby. This addiction is made worse by the fact that 3D printers can print parts to build another 3D printer. One day you purchase your first 3D printer off of the commercial list and the next thing you know you have 15 printers mass producing Star Wars figurines. I’m not judging. In fact, I am all for owning multiple printers. While Fused Filament Fabrication or FFF is a relatively narrow subset of additive manufacturing the printers that make up this category vary greatly in capabilities. Some 3D printers are setup to print large objects quickly while some are setup to print small high resolution parts. Further, some printers are able to print exotic materials and other printers can print multi-material parts. The point here is that there is a not a one size fits all printer, and in my opinion, the best way to get a printer that fits your needs is to source your own parts and build it!

Build it yourself.

Now I am not saying to come up with your own 3D printer design. There are a lot of great designs available online, and the point of this guide is to put those designs in front of your eyeballs. However, what makes these designs fall under DIY is that not only do you have to assemble it yourself, but more importantly you have to buy the parts individually (i.e. the parts don’t come in a kit). Purchasing your own parts gives you incredible flexibility to pursue accuracy by selecting the best-in-class components or to pursue savings by procuring cloned or used components. This process may seem intimating, but fortunately, most of these printers come with a bill of materials and links to vendors. However, it is a common occurrence for product links to be broken, so check out my video on How to Build a 3D Printer to learn how to pick the right parts.

FYI

It is strongly recommended to have access to a 3D printer prior to going down the DIY route. All of these builds call for a handful of 3D printed components. Unfortunately, I have had neither the time nor the money to build all of these printers. But from the printers that I have built, I have a feel for what designs are inherently flawed and what features are a must.

DIY 3D Printers

The below printers are ranked by the following criteria:

- Features– Designs that call for large build volumes, multiple extruders, 32-bit motherboards, and other premium features will result in a higher ranking. It’s important to keep in mind that even if the instructions don’t call for a certain feature that doesn’t mean you can’t modify the design to include it. This is one of the reasons why it is hard to rank DIY designs because the final 3D printer is what you make it.

- Difficulty – How hard is it to assemble the printer? This category is fairly self-explanatory. Keep in mind that the more capable the printer the more difficult the physical build and programming will be. If this is your first printer build then it is best to pick a simpler design (e.g. one extruder and a small to medium build volume).

- Community – When building a DIY printer no one is obligated to help you. Even worse, most printer designs lack an official manual. The community that surrounds the 3D printer can make up for this lack of documentation because it will be easier to get answers to your questions. A 3D printer with a designated sub-Reddit is usually a good indicator of a strong community.

#1 DIY 3D Printer: Voron 2

Features |

|

Difficulty† |

|

Community |

|

Cost |

>$1200 |

† More (brains) = more difficult

Features

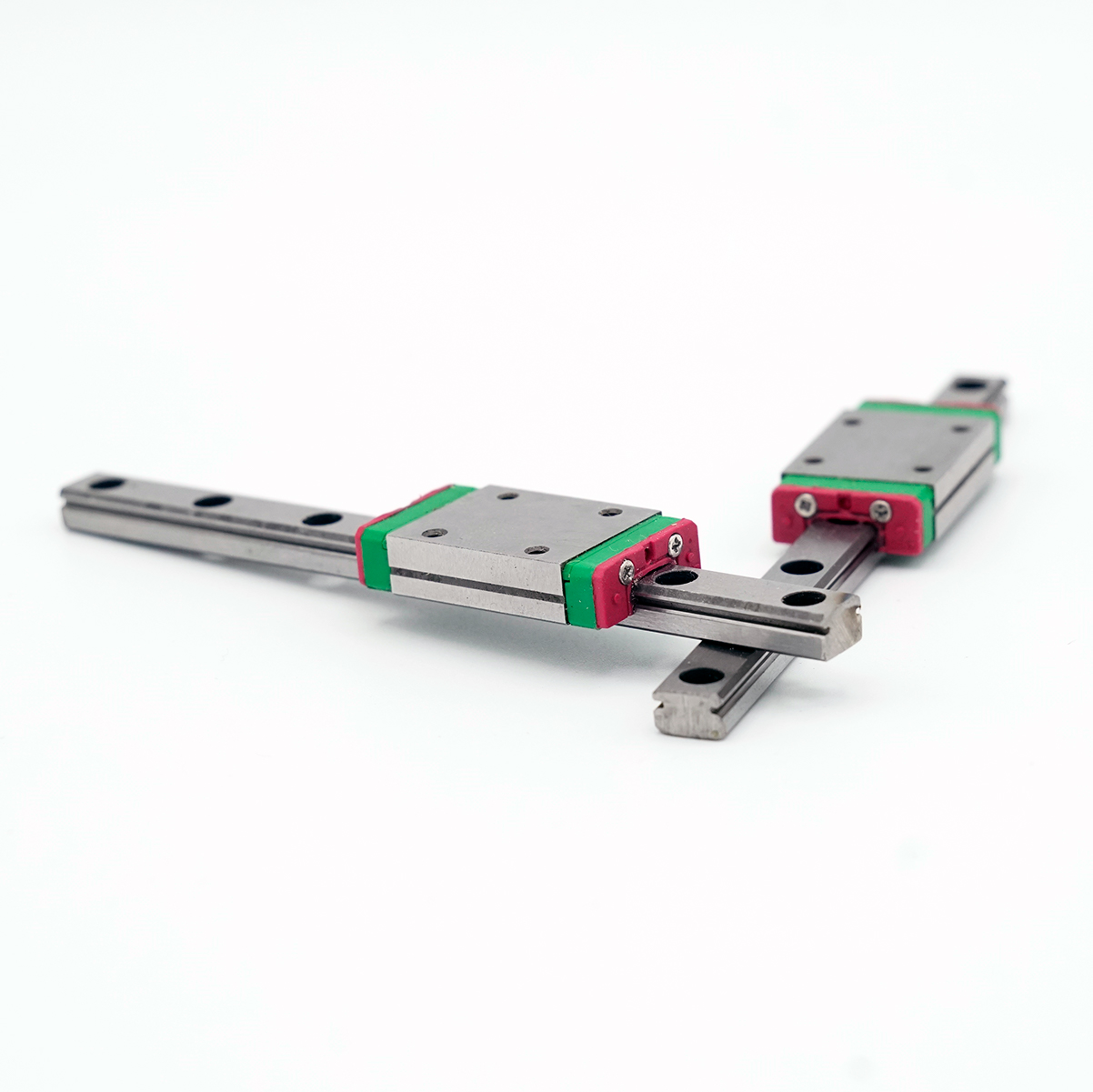

- CoreXY design with linear rails

- Auto leveling gantry

- Support for multiple build volumes: (250mm)3, (300mm)3, and (350mm)3

- Extruder can be quickly swapped

- Stationary build platform

- Enclosed

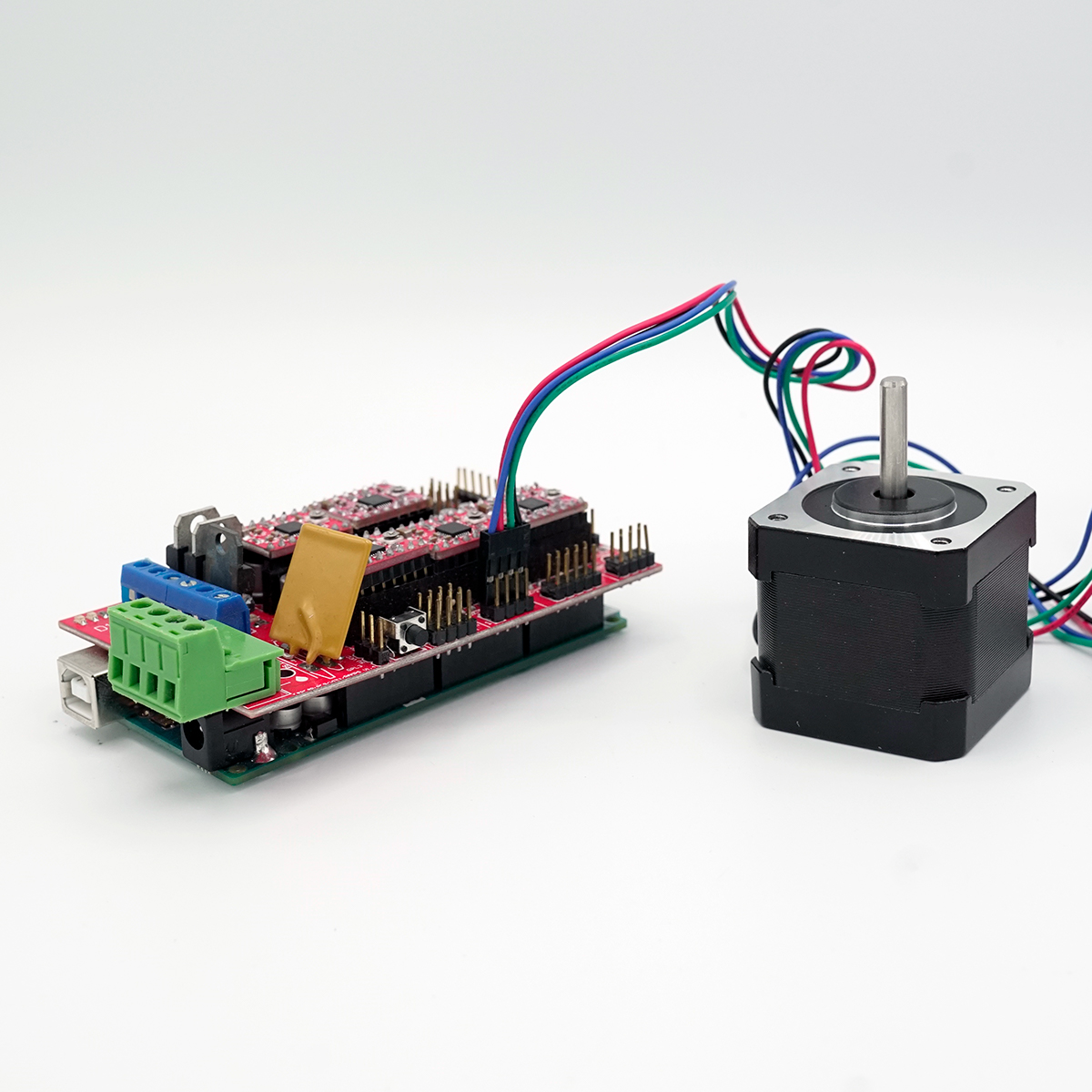

- Klipper Firmware running on a Raspberry Pi + 2 RAMPS

Difficulty

Community

A Closer Look at the Voron 2

#2 DIY 3D Printer: HyperCube

Features |

|

Difficulty† |

|

Community |

|

Cost |

<$350 |

† More (brains) = more difficult

Features

- Affordable CoreXY design with linear rods

- Requires only 4 stepper motors

- Proximity switch for auto bed leveling

- Can be easily enclosed

- Modest build volume (200 x 200 x 150mm)

- HyperCube remixes exist with more features

Difficulty

Community

A Closer Look at the HyperCube

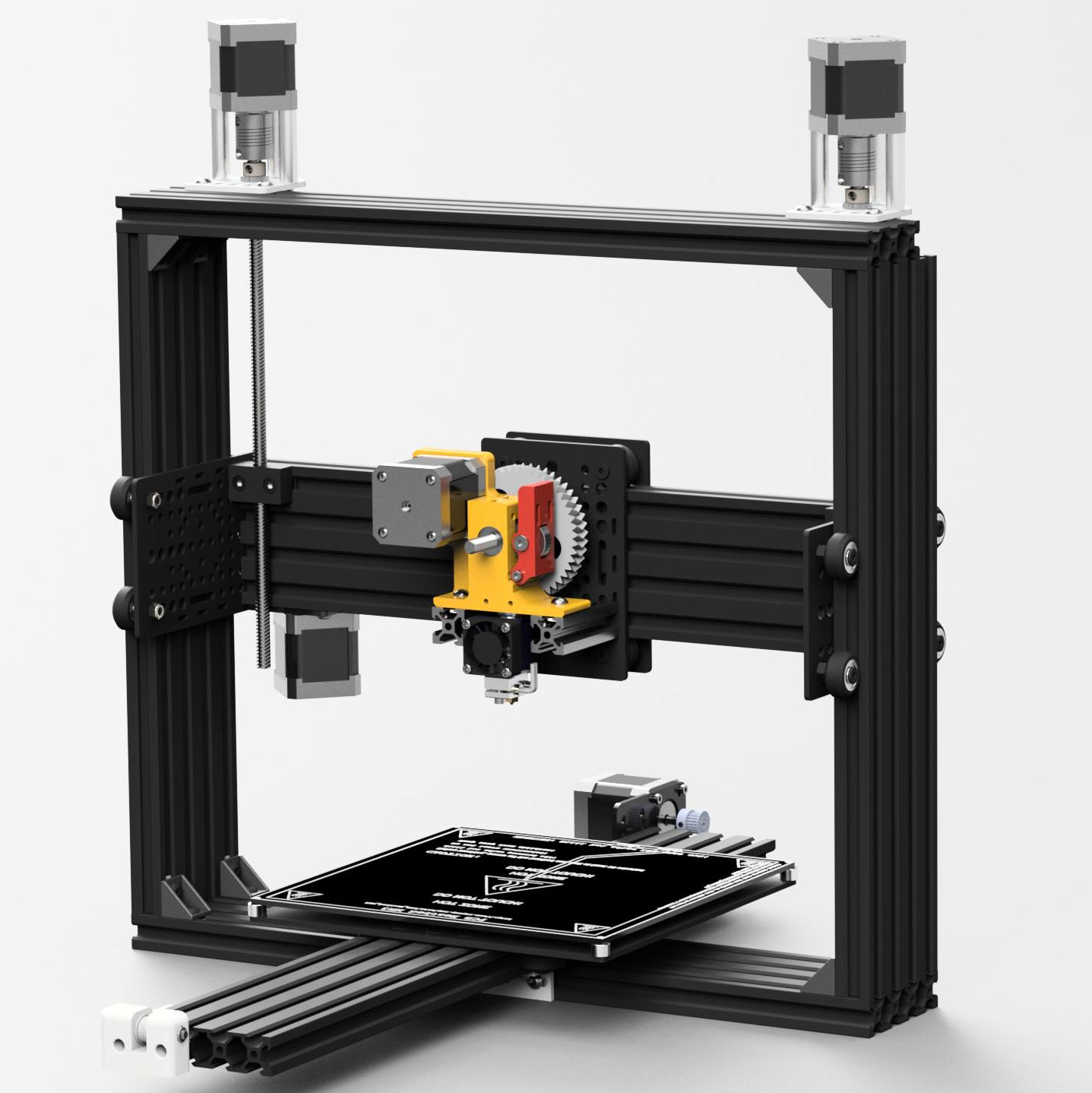

#3 DIY 3D Printer: Voxel OX

Features |

|

Difficulty† |

|

Community |

|

Cost |

>$1100 |

† More (brains) = more difficult

Features

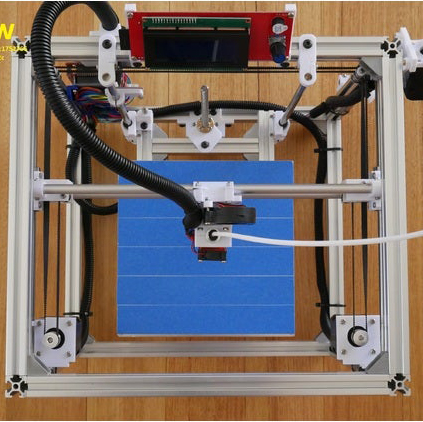

- Built on the V-Rail platform by OpenBuilds

- Sturdy frame

- Can be used as a CNC router!

- Easy to adjust build volume

- Auto bed leveling

Difficulty

Community

A Closer Look at the Voxel OX

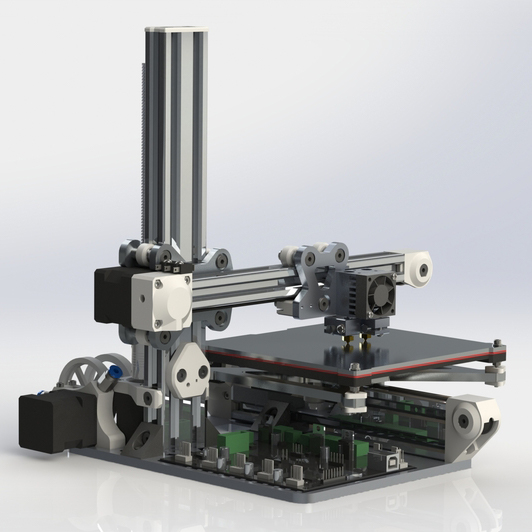

#4 DIY 3D Printer: Indie i2

Features |

|

Difficulty† |

|

Community |

|

Cost |

>$500 |

† More (brains) = more difficult

Features

- Small and lightweight

- Requires less aluminum extrusion = more affordable

- Native dual extrusion

- 32-Bit Smoothieboard

Difficulty

Community

A Closer Look at the Indie i2

You built a printer. Now what?

It's time to print! Check out my article on How to Calibrate a 3D Printer to make sure your printer is working as it should. Next, check out my list of The Most Useful Prints that you can do on your shiney new printer.